PERSONALIZED SUPPLEMENT MANUFACTURE

DARWINs companies have developed unique technologies to cater to an individual’s needs by personalizing the nutrient content in a supplement based on Lab analysis data. Lear how DARWIN has achieved personalized supplement manufacture on an industrial scale.

200+

700

20

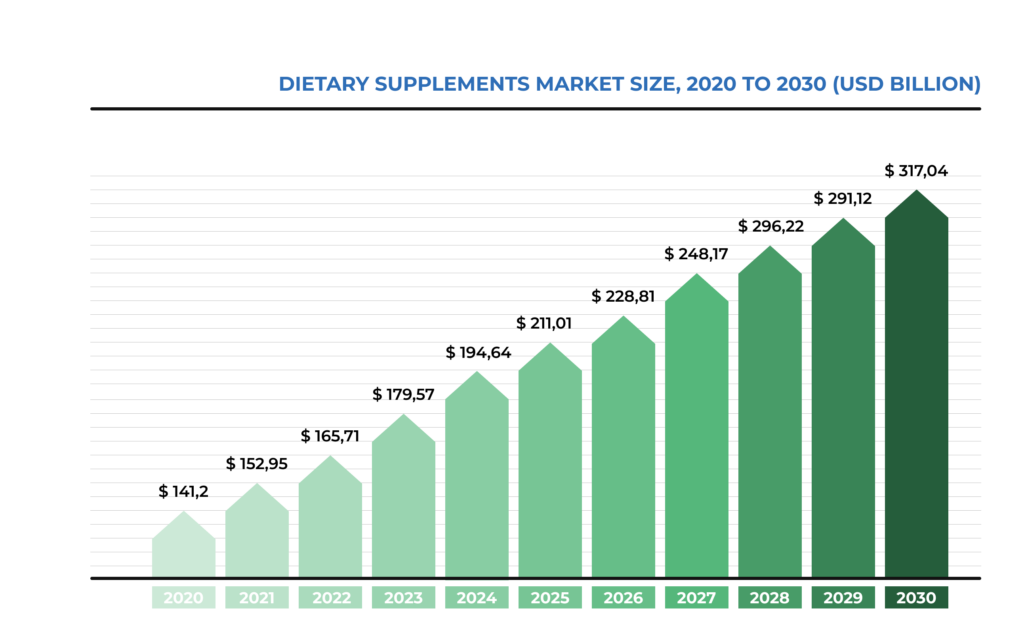

DIETARY SUPPLEMENT MARKET

IT STARTS WITH DATA

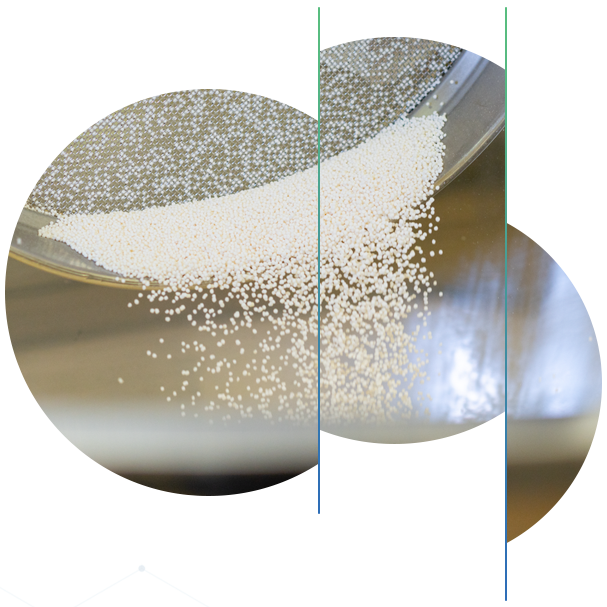

ENCAPSULATION

While there are numerous delivery methods of nutrients such as powders, pills, capsules or liquids, DARWIN chose to develop its own delivery method in form of small spheroid microtransporters. These 1.6mm large spheres are made of plant materials, that encapsulate one specific Nutrient in its indigestible cellulose matrix. The nutrient is locked in and protected from disadvantageous environmental influences such as light, oxygen and contact to other nutrients they may react with. DARWIN produces more than 50 different types of these microtransporters, that each contain a specific nutrient as a precise concentration. These batches of Microtransporters are the basis for the personalization step.

PERSONALIZATION

DARWIN developed proprietary technologies and machines, to precisely dose each type of Microtransporter into the personalized mixture for the customer. This currently semi automated process will be fully automated by 2023, at which time each personalization machine can hold 60 different types of Microtransporters and deliver unique mixtures at a rate of 15 seconds per product. With one machine at full capacity, this can generate up to €170 Million in annual revenue. After a short mixing step, the personalized mixture is ready for Packaging.

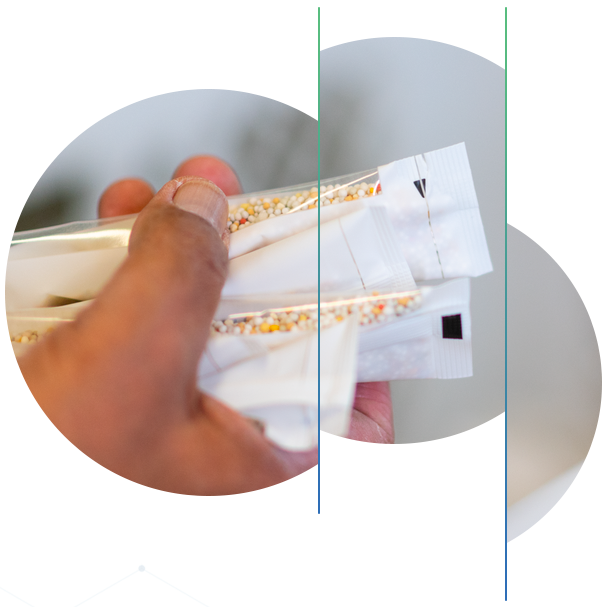

PACKAGING

Years of customer feedback has demonstrated, that easy transport of daily doses is important to our customers. For this reason, DARWIN has opted for daily stick packs, that contain all of the Microbeads the customer requires for the day. Traveling is as easy as throwing 3 Stick packs into the hand luggage. DARWIN developed specific machines that are able to fill stick packs with the required daily amount, seal them and print the customers name on each sachet. 30 to 90 such sachets are then packaged into a dispenser box, that is also personalized, gives detailed nutrient values and instructions of use. The finished product typically leaves the production facility 3 days after receiving the recipe.

PERSONALIZED SUPPLEMENTS AS A BUSINESS

Offering a science backed high end personalized supplement to customers engages them in a long lasting relationship with the company. In form of subscriptions we keep customers updated to changes in requirement, Science and technology of the product and deliver the next batch just in time to ensure a continuous supply for years. As personalized supplements are one of the core Products in DARWINS growth strategy, the current manufacturing facility at Novogenia, Austria is being doubled in size by the end of 2023. This new facility should allow for capacities of up to €200 Million in annual revenue from personalized supplements.

Other companies have also understood the value of encapsulation in microtransporters and personalization and so DARWIN is supplying its technology Platform and Production services as OEM projects to other companies.